Reliable CNC Systems Ensure Repeatability In Every Industrial Build

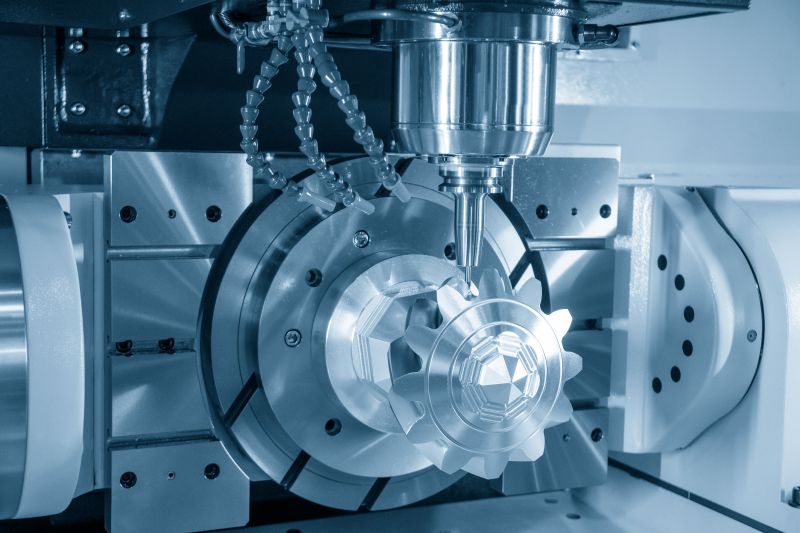

Reliable CNC systems play a crucial role in ensuring repeatability and precision in every industrial build, transforming the way manufacturing processes are executed across diverse sectors. Computer Numerical Control CNC machines have become the backbone of modern industrial production, enabling manufacturers to produce complex parts with consistent quality, high accuracy, and minimal human error. The fundamental advantage of CNC technology lies in its ability to automate and control machine tools via pre-programmed software, eliminating the variability that comes with manual operations. This automation guarantees that each component manufactured follows the exact same specifications, leading to exceptional repeatability which is vital for industries where precision is non-negotiable. In industrial environments, repeatability means the ability to produce identical parts or products time after time, regardless of the scale of production. This is particularly critical in sectors like aerospace, automotive, medical devices, and electronics, where even slight deviations can compromise safety, performance, or functionality.

Reliable CNC systems ensure that once a design is perfected and programmed, it can be replicated flawlessly across thousands or even millions of units. This consistency reduces waste, lowers production costs, and enhances overall efficiency by minimizing the need for post-production inspections or rework. A key aspect of CNC repeatability is the high level of control over every movement of the machine tools. CNC machines operate with tightly regulated motors, guides, and sensors that precisely dictate tool positioning, speed, and feed rates. Advanced feedback systems continuously monitor these parameters to correct any deviations instantly, ensuring the final output remains within strict tolerance limits. This closed-loop control mechanism is what differentiates reliable CNC systems from traditional machining methods, making them indispensable for producing parts with intricate geometries and tight tolerances. Moreover, CNC systems contribute to repeatability through their ability to store and reuse complex programs. Once a job is programmed, the software can be saved and recalled for future production runs, maintaining exact machining parameters without the need for manual recalibration. This repeatability extends beyond individual machines to entire production lines, where networked CNC systems coordinate multiple processes seamlessly.

Another factor reinforcing CNC reliability is regular maintenance and calibration protocols, which ensure machines operate at peak performance over time. Reliable online cnc service systems come equipped with diagnostic tools and error detection features that alert operators to potential issues before they affect production quality. This proactive approach to machine upkeep further guarantees consistent output and prolongs the life of expensive industrial equipment. In summary, reliable CNC systems are foundational to repeatability in industrial builds. They combine automated precision, real-time control, software programmability, and proactive maintenance to deliver consistent, high-quality products. This repeatability not only enhances manufacturing efficiency and reduces costs but also builds customer trust by ensuring that every product meets exacting standards. As industries continue to push the boundaries of design complexity and production speed, CNC technology remains an indispensable asset for achieving unwavering reliability and repeatability in every build.